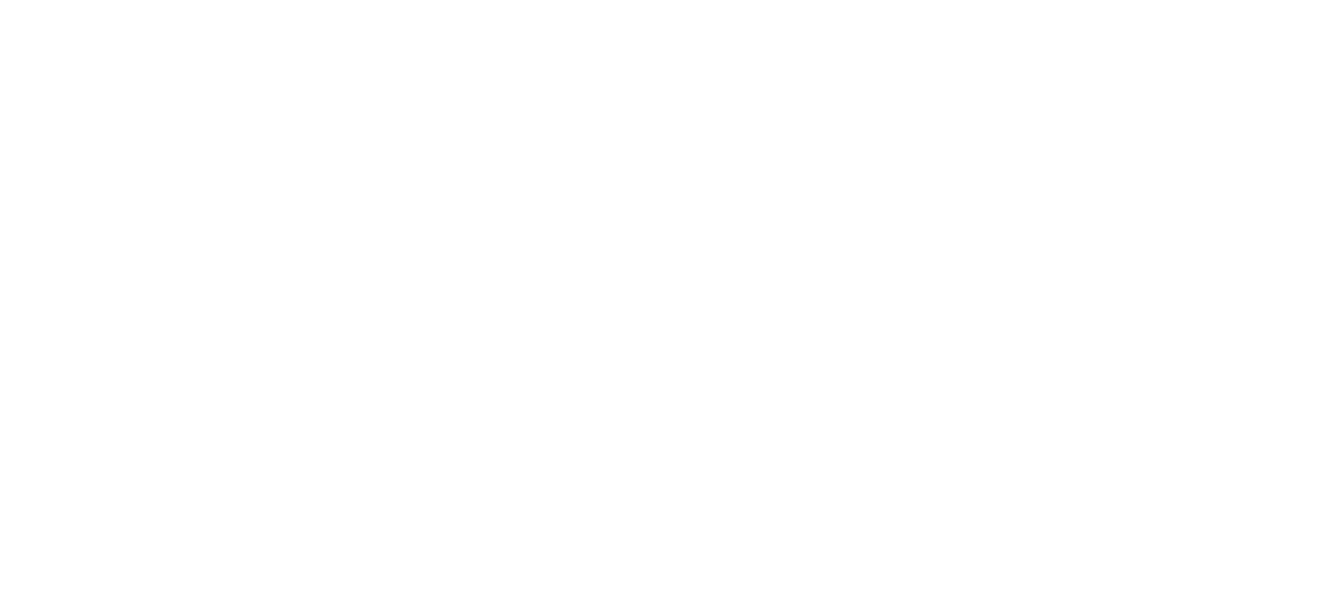

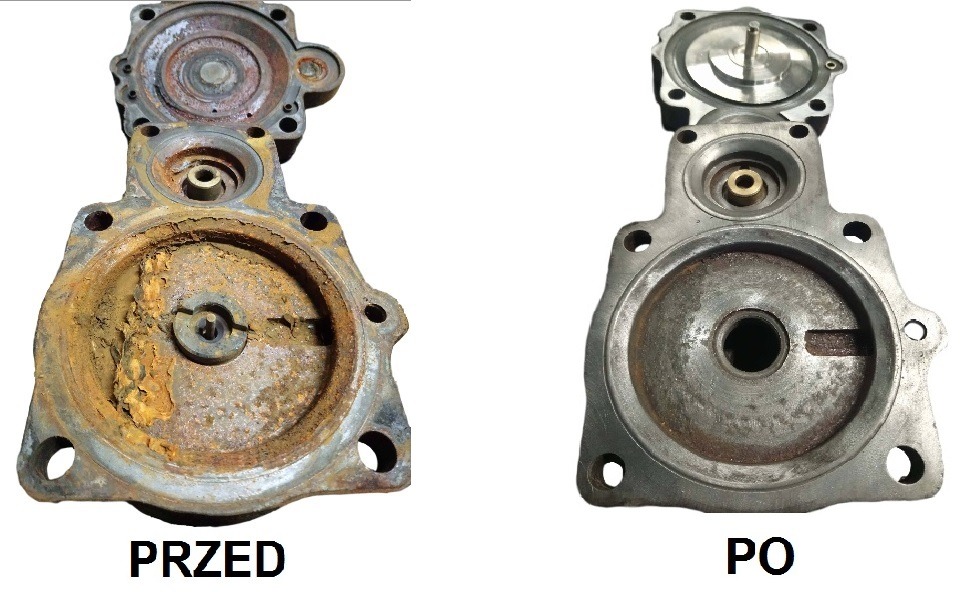

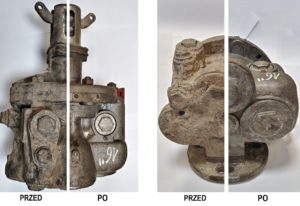

Visual effects following reconditioning

Brake valves, because of the arduous conditions in which they work must be scrupulously cleaned. The first phase of reconditioning is manual cleaning following which it is possible to begin dismantling of the valves. After this valves are washed using a TORRENT 500 pressure washer with a working temperature of 60 C and with the addition of detergent. A precise description of all stages in the reconditioning process can be found on Valve reconditioning process. Below we present a picture gallery of examples which show valves as they are received by us and after cleaning. .

Zawór rozrządczy systemu Oerlikon typu ESt3f

Zawory systemu DAKO CZ.

Zawór odwadniający systemu Sab-Wabco