Valve reconditioning process

Every valve is subjected to the following reconditioning process:

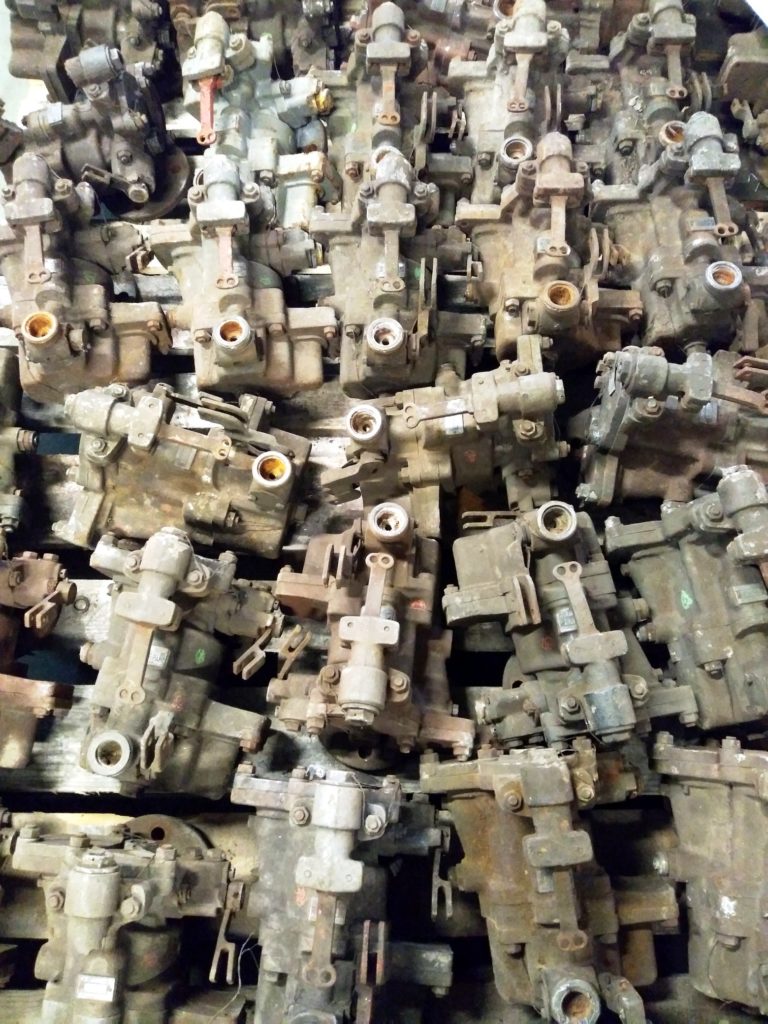

1. Acceptance of valves for repair

Valves for repair/reconditioning are checked on arrival – they are counted, their type is verified and their serial numbers logged. Their technical condition is assessed and any visible damage noted. Release of valves to the workshop for repair/reconditioning is preceded by the completion of a statement form signed for by the delivery driver

2. Pressure washing and cleaning of the valve.

3. Dismantling and checking that all parts are present.

4. Pressure washing and cleaning of all individual parts.

Washijng is carried out in a TORRENT 500 pressure washer at a temperature of 60 C with the addition of detergent. In the case of very severe congealed dirt the process is repeated.

5. Verification of the technical condition of each individual part and qualifying them either for repair or replacement.

Assessment of individual parts is based on the degree of wear and tear found. Those elements which are found to be out of limits are replaced with new ones while the rest are subjected to reconditioning.

6. Replacement of rubber seals.

Due to the life limits of rubber elements all of these are replaced. We make use of rubber seals provided by our approved suppliers.

7. Repair/replacement of all elements which show damage, excessive wear or which do not meet the requirements specified in the repair documentation.

All springs which go into a given valve are tested using a SAUTER FH 500N electronic force meter.. Springs which fail to meet specification are exchanged for factory new ones. Greasing of all internal valve parts.

All threads and moving parts and sub-assemblies are coated with a layer of GEASEN SYNTEX HT 2 (specifically formulated for pneumatic systems) or with silicon grease.

8. Re-assembly of valve

During reassembly individual elements and sub-assemblies are again checked and correct operation of moving parts is verified. In order to remove any residual moisture in the internal channels of the valve are flushed using a pneumatic pistol.

9. Montaż zaworu

Montaż zaworu dokonywany jest na tym samym stanowisku, na którym przeprowadzany był jego demontaż. Podczes tego procesu dokonywana jest powtórna weryfikacja części i podzespołów zaworu, a także ich wzajemnego spasowania. W celu usunięcia wszelkiej wilgotności kanały pneumatyczne w korpusie zaworu zostają przedmuchane za pomocą pistoletu pneumatycznego.

10. Checking and testing at the diagnostic station

Re-asesmbled triple valves are mounted on the computerized TEZER testing station. And the program appropriate to the valve being tested is selected for the task. Remaining valves are tested on dedicated diagnostic stations specific to them. Test reports conform to UIC or TSI standards. Successful testing is followed by print-outs of test reports.

11. Marking, painting and packing of valves

Following successful testing, valves are marked by a metal identity tag on the valve body next to the manufacturers label. Additionally, as protection against the entry of dirt during transport and storage, valve ports are sealed by means of a plastic combination seal/label.

12. Issue of quality certificates 3.1 or 3.2

The final stage is the issue of quality certificate 3.1 or 3.2 confirming the successful passing of all stages of the regeneration process in accordance with the technical requirements in accordance with ISO